Instructions

Instructions

When you first install the train horn system, turn on the air pump and allow it to fill the tank until the pressure switch turns the pump off. Do not let it exceed 125psi.

Now you can test your horn! Remember, the air compressor is not designed for continues usage. The air pump needs time to cool down between the horn blasts.

If you plan on using the horn every couple of minutes, you need to seriously consider purchasing a very large air tank.

Operation

Power from the toggle switch to your air pump should only

be turned on after you have honked the horn a couple of

times. The compressor does have an automatic shut off pressure

switch, but should that switch fail or a leak arise, the

pump will run continously and will drain your battery or

cause premature failure of your pump.

So remember to turn the toggle switch on, let the pump run

until the pressure switch cycles off your pump, and then

turn off the toggle switch. You will be able to tell when

the air pressure is low and you need to turn on the compressor

again.

All Kits require a Relay

Relay Terminal numbers are on the bottom of the relay.

You must unplug the connector to see the numbers.

Install the gauge with teflon paste or tape.

Relays, pressure switches, and inline fuses can be

purchased separately.

Air Pump

Locations for air pumps should be out of the weather elements such as snow, rain or extreme heat such as under-the-hood engine tempertures.

Under or behind seats and/or in the tool box are great locations. Also, trunk or spare tire area will work well.

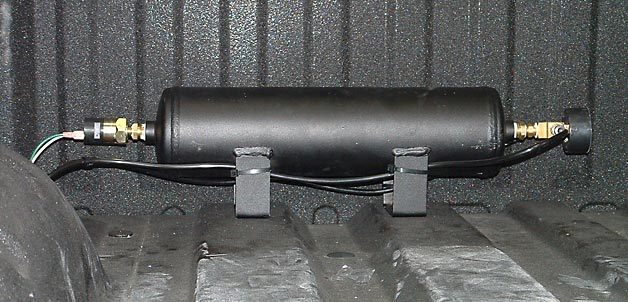

Air Tank

The air tank can be mounted anywhere you can fit your tank: Under your vehicle, in the bed of your vehicle, or inside your vehicle will work.

Horn Assembly

The horn is very durable it can be located on top or under the vechile, or under the hood.